Plumbing Equipments /

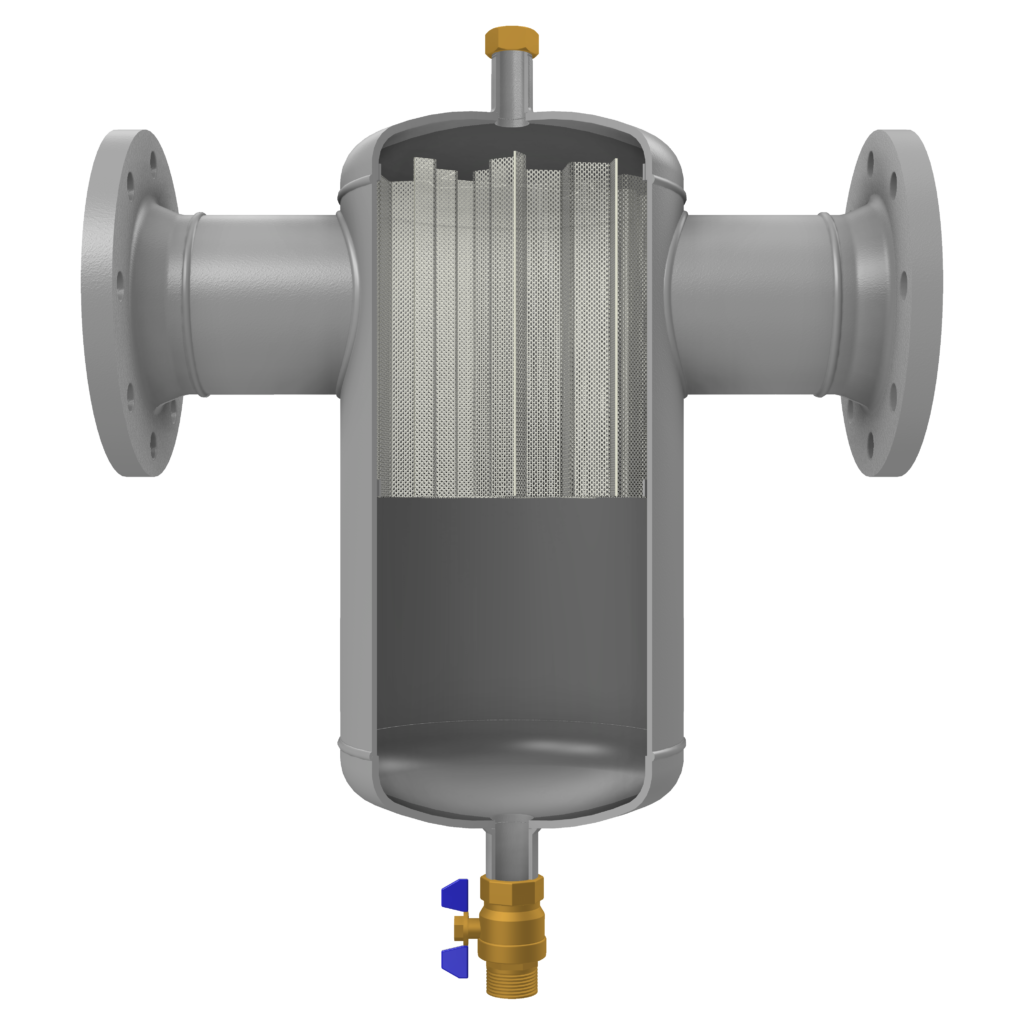

131.13 KTT STEEL DIRT SEPARATOR

KTT Steel Dirt Separator

The impurities mainly sand and rust particles circulating within the system cause

efficiency loss, failures in heating and cooling systems, clogging the pumps and control valves.

SPECIFICATIONS / USAGE AREAS

• Since the cleaning and maintenance of the classical type of dirt separators cannot be made easily by the user, they generally become out of function by time. With the help of ball valve on the bottom of the Steel Dirt Separator, cleaning can be done very easily.

• Specially designed stainless steel mesh filters are present.

• Percentage of glycol in the heating system is maximum 50%

• Accumulated impurity volume is much bigger according to classical dirt separators.

Needed periodic cleaning is much more less.

Features

Maximum Operating Temperature

110 °C

Maximum Operating Pressure

1000 kPa (10 bar)

Connection Sizes / Pressure Class

Flanged Connection: DN50-DN150 / PN16

Welded Connection: 60,3 mm-168,3 mm

(Please contact for products between DN200- DN600)

Filter Material

Stainless steel

Outer Surface Protection Paint

Electrostatic Powder Paint

Manufactured in accordance with 2014/68/EU Pressure Equipment Directive and EN 13445-3 Standards.

Flanged Steel Dirt Separator

| Code | 131.13.16.1 | 131.13.17.1 | 131.13.18.1 | 131.13.19.1 | 131.13.20.1 | 131.13.21.1 | |

| A | mm | DN50 | DN65 | DN80 | DN100 | DN125 | DN150 |

| 2” | 2½” | 3” | 4” | 5” | 6” | ||

| B | mm | 420 | 420 | 500 | 504 | 635 | 635 |

| C | mm | 3/4” | 3/4” | 3/4” | 3/4” | 3/4” | 3/4” |

| D | mm | 322 | 322 | 384 | 384 | 480 | 480 |

| E | mm | 480 | 480 | 556 | 556 | 725 | 725 |

| F | mm | 1” | 1” | 1” | 1” | 1” | 1” |

| Weight | kg | 13 | 15 | 19 | 22 | 37 | 40 |

| Volume | lt | 7 | 7 | 15 | 15 | 45 | 45 |

| Kv | m3/h | 75 | 150 | 180 | 280 | 450 | 720 |

| Min.-Max. Flow rate | m3/h | 8-12 | 10-22 | 18-30 | 28-48 | 45-71 | 67-105 |

Kv = Q / √ΔP… Q = Water flow rate (m³ / h)

ΔP = Pressure loss on the product (bar)

Welded Steel Dirt Separator

| Code | 131.13.16.2 | 131.13.17.2 | 131.13.18.2 | 131.13.19.2 | 131.13.20.2 | 131.13.21.2 | |

| A | mm | DN50 | DN65 | DN80 | DN100 | DN125 | DN150 |

| 60,3 | 76,1 | 88,9 | 114,3 | 139,7 | 168,3 | ||

| B | mm | 330 | 330 | 400 | 400 | 525 | 525 |

| C | mm | 3/4” | 3/4” | 3/4” | 3/4” | 3/4” | 3/4” |

| D | mm | 322 | 322 | 384 | 384 | 480 | 480 |

| E | mm | 480 | 480 | 556 | 556 | 725 | 725 |

| F | mm | 1” | 1” | 1” | 1” | 1” | 1” |

| Weight | kg | 8 | 8 | 11 | 12 | 24 | 24 |

| Volume | lt | 7 | 7 | 15 | 15 | 45 | 45 |

| Kv | m3/h | 75 | 150 | 180 | 280 | 450 | 720 |

| Min.-Max. Flow rate | m3/h | 8-12 | 10-22 | 18-30 | 28-48 | 45-71 | 67-105 |

Kv = Q / √ΔP… Q = Water flow rate (m³ / h)

ΔP = Pressure loss on the product (bar)

KODSAN reserves the right to change the product specifications, technical information and installation diagrams without any notifications.

All information written on this page can not be copied or used without permission of KODSAN. Kodsan can not be held responsible if any of the technical information and

schemes are considered exemplary by third parties.